Updated 1 day ago

Recycling solar panels: What happens when they no longer work?

Written by

Ben Zientara

Find out what solar panels cost in your area

Solar panels are made to last, but solar panel recycling is still an important topic.

Barring damage from natural disasters or accidents, modern solar panels have an expected lifetime of 30 years or more.

Nearly all solar panels in the world were installed after 2009 and come with a guarantee that they’ll produce at least 80% of their rated power output after 25 years. Most panels on the market will do better than that, producing about 85% of their rated output after 30 or 35 years.

But what happens to solar panels when they stop working? Can they be recycled, or do they sit in a landfill? Let’s take a closer look at solar panel recycling and what happens to solar panels when their usable life is over.

Can solar panels be recycled?

The short answer is yes, solar panels can be recycled. About 80% of a solar panel’s weight is glass and aluminum, two highly recyclable materials.

However, recycling solar panels isn’t as easy as it sounds. It can be difficult to separate all the different materials for proper recycling because of how solar panels are sealed and constructed.

Also, most of the solar panels installed in the United States haven’t even reached the end of their lifespan yet, meaning the solar panel recycling industry hasn’t taken off.

The solar panel recycling process

Most materials used to make a c-Si solar panel can be reclaimed through recycling processes. In the United States, the law that governs the disposal of solar panels is the Resource Conservation and Recovery Act (RCRA), which applies to all solid waste.

The ideal process would be to recover as much recyclable material from the panel as possible. Method’s listed by the EPA include some or all of the following steps:

Remove the solar panel frame and junction box.

Separating the glass and silicon wafer through thermal, mechanical, or chemical processes.

Separating and purifying the silicon cells and specialty metals through chemical and electrical techniques.

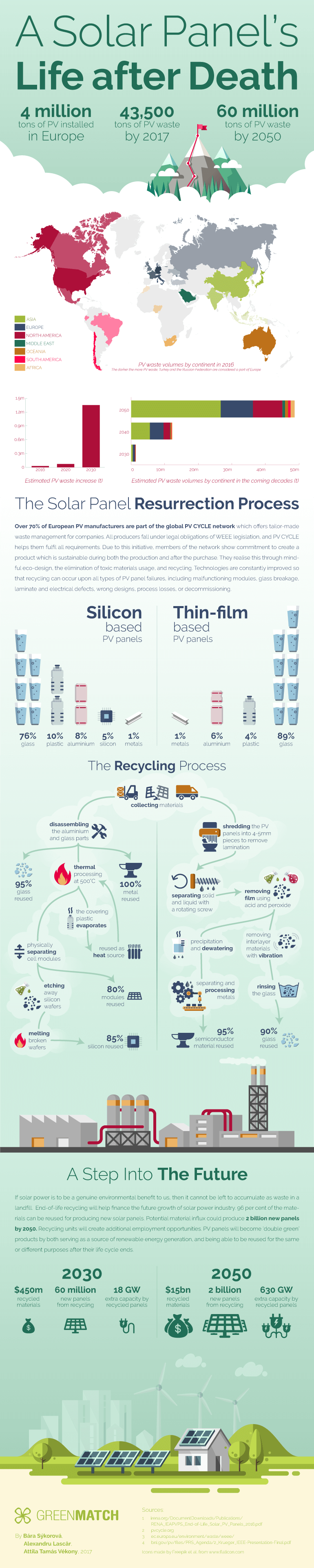

This infographic was produced in 2017 by GreenMatch, a UK-based provider of quotes for green energy products from multiple providers.

What are solar panels made of?

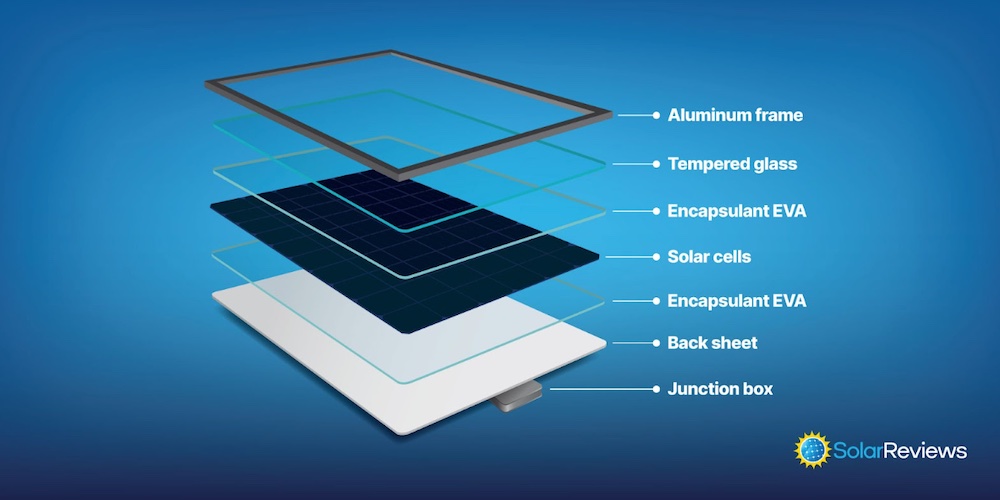

Most home solar panels sold today are made of crystalline silicon solar cells, also known as “c-Si” panels. C-Si panels consist of several different layers sandwiched together.

These layers include:

A frame made from aluminum

Low-iron glass

Crystalline-silicon solar cells

A protective backsheet

The layers are fairly simple, and when combined together using heat to seal the encapsulant and bond it to the glass, form a very sturdy panel; built to last.

Are solar panels hazardous waste?

Although most of the materials on solar panels, like aluminum, plastic, and glass, are easily recycled, some of the other essential components are different. Different varieties of solar panels contain metals present in the semiconductor and solder.

Some of these metals, such as lead and cadmium, are harmful to human health and the environment at high levels. According to the U.S. Environmental Protection Agency (EPA), discarded solar panel waste can be considered hazardous if these metals reach a high enough level.

Fortunately, solar panels don’t contain high enough levels of hazardous material to be concerned about anytime soon, but we must find an effective recycling and disposal solution before this becomes an issue.

Where can I recycle my solar panels?

Chances are, you haven’t had to worry about this yet. But – it’s important to know for the future!

In the United States, where there are no current laws specifically governing the recycling of solar panels, the Solar Energy Industries of America (SEIA) developed a national recycling program and partnered with multiple companies that can accept solar panels for recycling. Those partners are listed on SEIA’s website. SEIA is still seeking new PV end-of-life management partners to add to its growing list.

Some solar panel manufacturers have also started to develop programs for recycling. Qcells recently announced a partnership with SOLARCYCLE, a technology-based solar recycling company.

First Solar is another. manufacturer that offers solar panel recycling. You can inquire about solar panel recycling by filling out a form on their website.

Solar panel recycling: Looking towards the future

Humanity has a two- or three-decade runway to learn how best to deal with solar panels at the end of their useful life, but by 2030, it’s expected solar panels will account for one million tons of waste. Recycling all the materials that go into making them is essential because those old panels will represent billions of dollars in valuable resources, and some materials used are potentially toxic if discarded in a landfill.

We have the perfect proving ground: as solar panel production ramps up, there will inevitably be a need to recycle broken panels, duds, and panels destroyed by natural disasters. Now is the time for governments and the industry to set the standards for recycling the panels that can be used as the amount of solar waste increases in the coming decades.

Ben Zientara is a writer, researcher, and solar policy analyst who has written about the residential solar industry, the electric grid, and state utility policy since 2013. His early work included leading the team that produced the annual State Solar Power Rankings Report for the Solar Power Rocks website from 2015 to 2020. The rankings were utilized and referenced by a diverse mix of policymakers, advocacy groups, and media including The Center...

Learn more about Ben Zientara